Today, I went to one of my local electronics stores to pick up equipment and stare at 3D printers. Ultimately, I picked up a ADXL345 accelerometer to calibrate my wife’s printer resonance and decided it’s should still be worth rebuilding my decade old 3D printer.

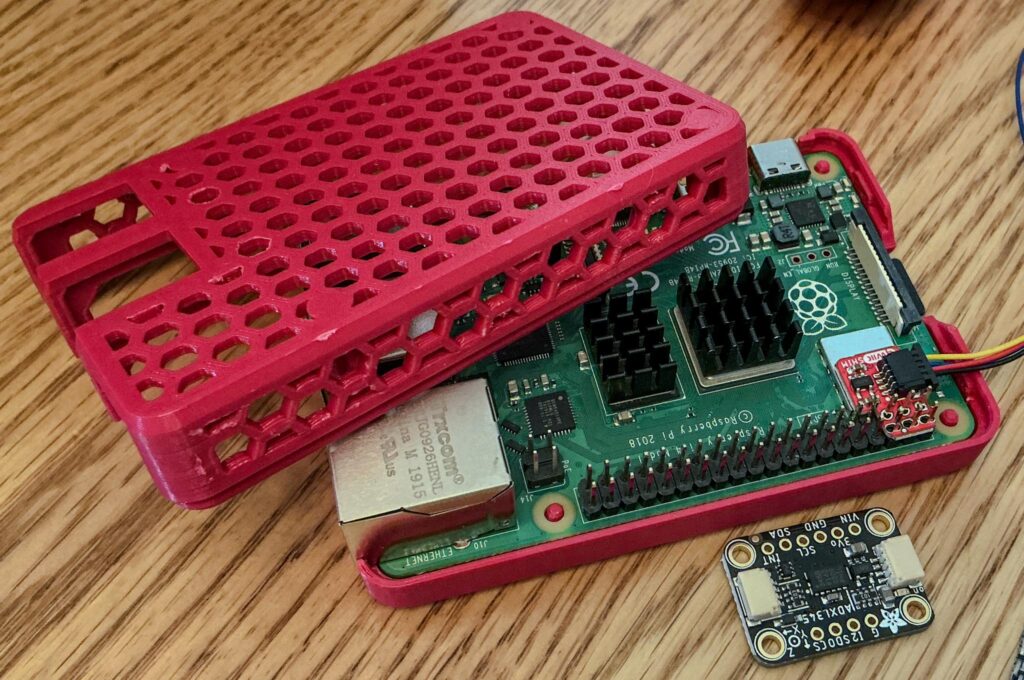

Raspberry Pi 4 with a 3D printed snap case, QWIIC Pi Shim, and Adafruit ADXL345.

My QWIIC cables arrive tomorrow. 😊

I probably spent well over half an hour looking (and possibly touching 🤫) their machines to see how tight tolerances were for different prices and tiers. I was a bit disappointed with some of the mid tier machines as their print heads were less tight on the Y axis, but I’d imagine that wouldn’t matter much if the print heads are well balanced in vertical weight.

I have a number of orders both arrived and am waiting on. I ordered a new board and extrusion parts for my (very outdated) 3D printer. My plan is to convert it from a 2.85mm (aka 3mm) bowden into a 1.75mm direct drive. I’ve had a lot of mixed thoughts on this, because I sourced a tight tolerance bowden many years ago and I like the weight reduction, but direct drive is more capable and standardized. The entire process will be nearly a rebuild, using the old chassis and motors.

- My Galileo 2 extruder kit arrived, but I need to replace my main board to print in ASA. (I won’t risk melting my wife’s machine for this)

- My Pi 5 CM arrived to power my new main board.

- I’m waiting on an ICM-20948, Manta M8P V2.0, TMC2240 drivers, and a Mosquito hotend.

This is going to be a very involved rebuild, I’m looking forward to it!

Leave a Reply